What is Manufacturing Analytics?

It is meticulously designed to deliver exceptional analytics, offer insight into

the plant floor, and empower manufacturers to achieve success consistently, every day

Manufacturing analytics represents the forefront of advanced analytics in the manufacturing sector, aligning with the principles of Industry 4.0. Leveraging Artificial Intelligence algorithms, Machine Learning modeling, and visualizations, it processes extensive datasets to provide insights that enhance operational performance and profitability.

In the domain of process manufacturing, the adoption of advanced analytics has been slower compared to other industries, primarily due to the immense size and complexity of its datasets. While Advanced Process Control (APC) systems have historically boosted productivity, their high operational costs restricted their application to key assets and processes.

The advent of new manufacturing analytics, powered by AI and ML, has revolutionized the landscape. It enables the affordable tracking, collection, and analysis of data from every machine and process. Moreover, its user-friendly interface caters to non-data scientists, making analytics accessible across the entire manufacturing spectrum.

Manufacturing Industry Analytics Solutions

Following are the Manufacturing Services we offer

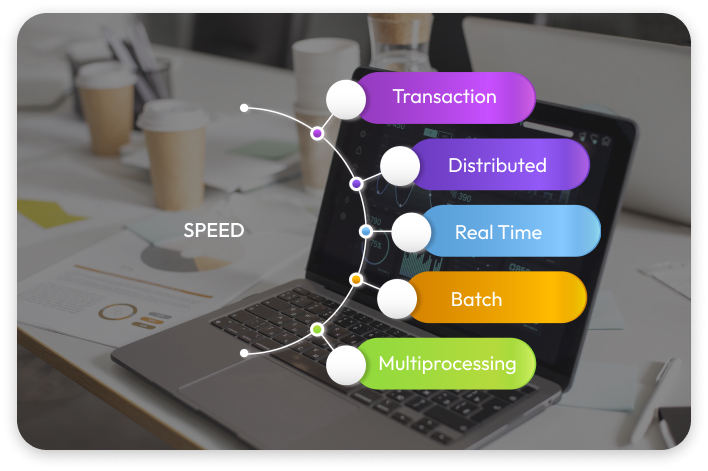

Data Management

Initiating a data-first culture begins with robust manufacturing data management and governance. Our customized solutions are designed to meet both your immediate and future data storage needs, ensuring a seamless and scalable approach to data management.

Data Analytics

In the manufacturing environment, data is continually generated at every juncture. Yet, its full potential remains confined within silos, restricting its utility. Our specialists are adept at unleashing the true power of your data by providing near-real-time insights, thereby transforming raw information into actionable intelligence.

Technology Consulting

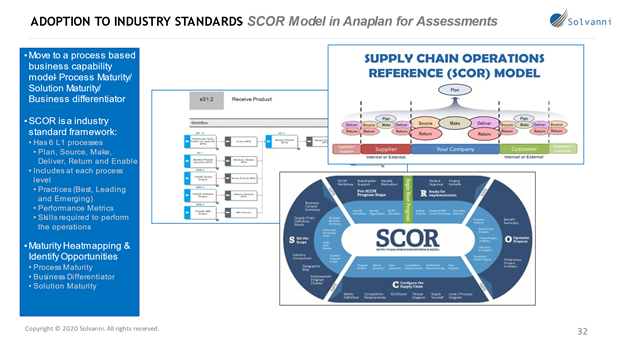

Harness the collective expertise to generate forward-thinking recommendations tailored to meet your future technology requirements. Engage in dynamic brainstorming sessions with our team of techno-functional experts to guide you in selecting the optimal technology platform for your manufacturing unit.

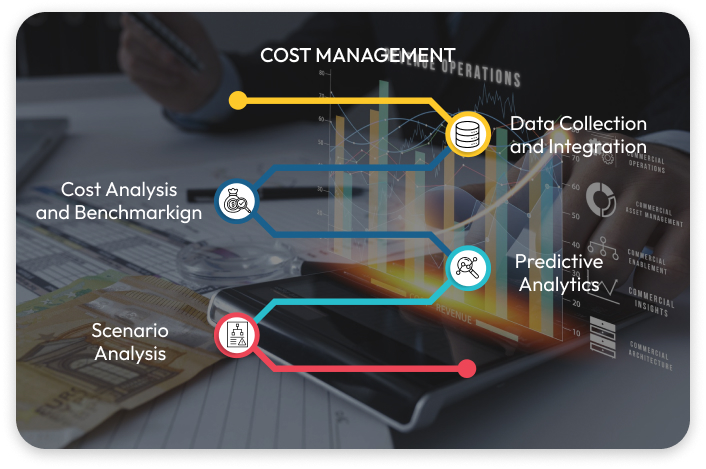

Business Planning

In an era where consumers have an abundance of choices, agile scenario modeling and business planning have become indispensable for fostering business success. Our services are tailored to assist you in mitigating risks associated with demand fluctuations, ensuring resilience and adaptability in a dynamic market landscape.

Advantages of Manufacturing Analytics

Empowering manufacturers to make swift decisions and enhancing business automation, manufacturing analytics tools seamlessly link machines to sensors, transmitting data to cloud platforms. These platforms, with their accelerated data processing capabilities, outpace human capabilities, providing a data-rich resource that expedites decision-making and optimizes overall company operations. The main advantages of Manufacturing Analytics includes:

- Increased income

- Helps in avoiding mistakes following industry rules

- Improved processes and cost saving

- Customer satisfaction

How Can Manufacturing Analytics Address Key Challenges?

ACG’s manufacturing analytics, with versatile capabilities, can address a myriad of challenges across different facets of

manufacturing operations, ultimately contributing to improved performance, quality, and efficiency. Some of them are as follows: